Fulfilment Rules and Pick List Rules - How They Work

Fulfilment Rules

Fulfilment Rules are logic-based rules that process sales orders as they arrive in Stok.ly.

Fulfilment Rules assign your sales orders or items in sales orders to couriers and courier services or freight services.

As you process sales orders in Stok.ly, all the shipping information is pushed directly to your courier.

Cut out data input and human error and process sales orders in bulk.

Mix and match automation and manual processing to fit your business model.

Pick Rules

Once Fulfilment Rules have run, Pick Rules run.

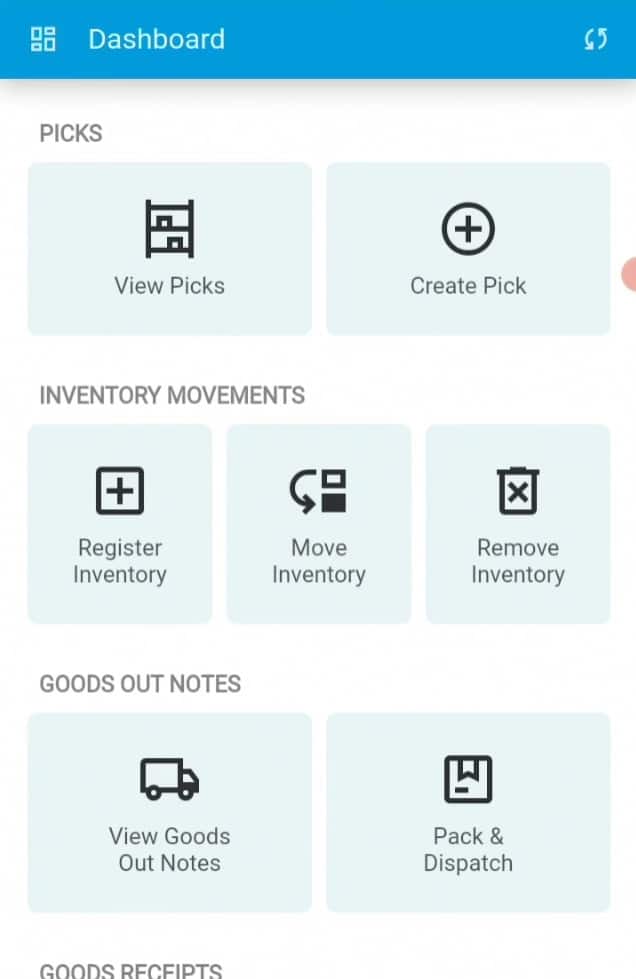

Pick Rules create Batch Pick Lists.

Many of our customers use a mix of automation and manual tasks to manage the creation of Pick Lists.

For some customers, Picks need to be separated into “small” “medium and “large” items to match trolleys or “totes”.

For others, Picks need to be separated into B2C and B2B orders.

Pick Lists can be sent to warehouses, depots or shops.

Picks can be split across zones, teams or individuals in a warehouse.

Fulfilment & Picks Rules can be scheduled to match shift patterns or courier collection times.